Tuesday, 31 December 2024

Wednesday, 25 December 2024

Saturday, 23 November 2024

Exair Air Knives - Efficient Blowoff Solutions

In this issue, we're excited to spotlight our ExairAir Knives, the ultimate solution for efficient blowoff, cooling, drying, and cleaning applications.

What Makes Exair Air Knives Stand Out?

- Super Air Knife : With a 40:1 air

amplification ratio, it provides the best performance, making it the most

efficient choice for all applications. Read

more

- Standard Air Knife: Offers a 30:1 air

amplification ratio, providing good performance at a lower cost. Read

More

- Full-Flow Air Knife: Ideal for tight spaces

with a 30:1 air amplification ratio, balancing performance and cost. Read

More

Applications and Benefits

Our Air Knives are perfect for conveyor cleaning, part drying, scrap

removal, pre-paint blowoff, and cooling wide webs. They deliver a uniform sheet

of laminar airflow with hard-hitting force while remaining exceptionally quiet.

For more information, visit our website (www.vivekengineers.net)or contact

our Application Engineers for personalized solutions. Don't forget to follow us

on social media for updates and insights!

Friday, 1 November 2024

New Intellistat Ion Air Gun for Static Elimination in Sensitive Processes

EXAIR's Intellistat® Ion Air Gun is a handheld and lightweight solution to static elimination in clean processes, electronic test facilities, laboratories and clean rooms. Rated Class 5 for ISO 14644-1 and controlled environments, the Intellistat has secured a patent highlighting it’s unique design and operation that represents EXAIR’s continued advancement in clean room static elimination.

The Intellistat was designed to consume minimal compressed air while simultaneously delivering precise blow-off, and exceptional static decay rates. Intended for cleanrooms and processes sensitive to particulate or static, the Intellistat produces clean, ionized airflow that is essential in removing troubling dust or static charges without compromising production. Made from durable static dissipative polycarbonate, the Intellistat assures its usefulness in applications requiring non-conductivity such as circuit board or electronics manufacturing, as well as blowoff applications like cleaning lenses or removing debris from medical products. It also features LED lights to ensure proper functionality and a lightweight frame for prolonged use.

The Intellistat is a low maintenance solution that is UL listed and CE compliant, adding to a long line of EXAIR static eliminator products including Super Ion Air Knives, Ion Air Cannons, Ion Air Guns, Ionizing Bars and Ionizing Points and more.

|

Other Static

Eliminators Pruducts |

|

|

|

|

Vivek Pneutech Solutions Pvt. Ltd. |

|

#22, 1st Floor, 1st Cross, Bilekahalli Indl. Area |

|

|

Monday, 16 September 2024

The Ultimate Guide to Exair Gen4 Ionizing Bars: How They Work and Why Your Industry Needs Them

In industries where static electricity causes operational disruptions, quality issues, or safety concerns, finding an efficient solution is crucial. Enter Exair Gen4 Ionizing Bars—a powerful and reliable tool for static control. Let’s dive into what makes these bars indispensable for modern industrial environments.

What Are Exair Gen4 Ionizing Bars?

Exair Gen4 Ionizing Bars are anti-static devices that neutralize static electricity on surfaces. Designed for applications where unwanted static can lead to operational inefficiencies, product contamination, or even safety risks, these bars eliminate the charge by emitting ions that neutralize static buildup.

How Do Exair Gen4 Ionizing Bars Work?

Key Features of Exair Gen4 Ionizing Bars

Efficient Static Neutralization: Exair Gen4 Ionizing Bars provide fast and effective static elimination, which improves product quality and reduces downtime.

Variety of Sizes: Available in different lengths, these bars can be customized for various industrial applications, ensuring the right fit for your needs.

Durable Construction: Built with rugged materials, Exair Gen4 Ionizing Bars are designed to withstand harsh industrial environments, offering long-lasting performance.

Maintenance-Free Operation: With no moving parts and minimal upkeep required, Exair Gen4 Ionizing Bars are designed for long-term operation without frequent intervention.

Safe to Use: These Gen4 Ionizing Bars are armored with rugged metal and electromagnetically shielded cable, ensuring they are safe for use in sensitive environments, including those where electronic components are present.

Industries That Benefit from Exair Gen4 Ionizing Bars

Plastics Manufacturing: In plastic molding and film extrusion processes, static can cause dust and debris to cling to surfaces, degrading product quality. Ionizing bars eliminate these issues, improving the finish and clarity of the products.

Printing and Packaging: Static can cause materials to stick together or misalign, leading to jams or inaccurate cuts. Exair Gen4 Ionizing Bars ensure smooth handling and reduce waste caused by static-related errors.

Textile Industry: In textile production, static buildup can attract dust and dirt, leading to contamination. By neutralizing static, ionizing bars help maintain cleanliness and quality.

Electronics Assembly: Static discharge can damage sensitive electronic components. Exair Gen4 Ionizing Bars eliminate the risk of electrostatic discharge (ESD), protecting both components and workers.

Benefits of Using Exair Gen4 Ionizing Bars

Enhanced Product Quality: By eliminating static, you reduce the risk of contamination and defects, leading to higher-quality products.

Increased Operational Efficiency: With reduced static-related downtime, your production lines can run more smoothly, increasing throughput.

Cost Savings: Less downtime, fewer defects, and reduced waste all contribute to cost savings in the long run.

Improved Safety: In some cases, static buildup can create unsafe working conditions, especially in environments where flammable materials are used. Exair Gen4 Ionizing Bars help mitigate these risks.

Exair Gen4 Ionizing Bars Specifications

Would you like more detailed information or have specific questions about its operation or applications?

Please Click Here to visit our website.

Vivek Engineers #22, 1st Floor, 1st Cross, Bilekahalli Indl. Area, Adj. IIMB Compound, Bannerghatta Road, Bangalore - 560 076 |

Friday, 30 August 2024

Stop using liquid coolants! Now time to go for Exair Cold Gun Aircoolant system

If you're considering switching from liquid coolant to an air-based solution like the Exair Cold Gun, here are some benefits :

Benefits of Using Exair Cold Gun Over Liquid Coolant:

- Cleaner Operation: No liquid mess or the need for coolant disposal, which can simplify maintenance and reduce environmental impact.

- Reduced Costs: Eliminates the ongoing costs associated with purchasing, maintaining, and disposing of liquid coolants.

- Non-Contaminating: Since no liquids are involved, there's no risk of coolant contamination or residues on parts.

- Consistent Cooling: Provides a steady, reliable stream of cold air, reducing the risk of overheating during machining.

- Environmentally Friendly: Uses only compressed air, avoiding the environmental concerns related to chemical coolants.

- Improved Safety: Eliminates the hazards associated with handling and exposure to chemical coolants.

- Compressed Air Powered: The Cold Gun uses compressed air to generate cold air, which makes it efficient and environmentally friendly since it doesn't rely on electricity or refrigerants.

- No Moving Parts: The lack of moving parts means there is minimal wear and tear, resulting in lower maintenance costs and longer operational life.

- Temperature Drop: The tool can lower the temperature of the air by as much as 50°F (28°C) from the ambient temperature.

- Versatile Applications: It's commonly used in CNC machining, metal cutting, and other processes where excessive heat could damage tools or parts.

- Quiet Operation: The Exair Cold Gun is designed to operate quietly, making it suitable for environments where noise reduction is important.

Would you like more detailed information or have specific questions about its operation or applications?

Please Click Here to visit our website.

Vivek Engineers #22, 1st Floor, 1st Cross, Bilekahalli Indl. Area, Adj. IIMB Compound, Bannerghatta Road, Bangalore - 560 076 |

Friday, 2 August 2024

How Exair Air Nozzles Save Money and Compressed Air ?

Industrial air nozzles are widely used in India across various industries for applications such as cooling, drying, blowing off debris, and cleaning. But it is really complicated to find out a proper nozzle based on quality and cost.

Now I am going to explain you how you can save Money and Compressed Air if you select EXAIR Engineered Air Nozzles in India.

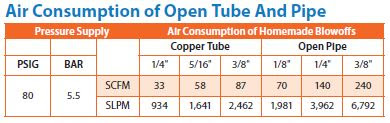

One of the worst culprits for inefficient air use is open pipe blow-offs. This would include cheap air guns, drilled holes in pipes, and tubes. These are very inefficient for compressed air and can cost you a lot of money. I will share a comparison to a 1/8” NPT pipe to an EXAIR Mini Super Air Nozzle. (Reference below). As you can see, by just adding the EXAIR nozzle to the end of the pipe, the company was able to save per year. That is some real savings.

The table above shows the air consumption for typical homemade blow offs. The pages that follow give the air consumption and other data on EXAIR's Air Nozzles and Jets. Consider the following example where a Model 1102 Mini Super Air Nozzle replaces an 1/8" open pipe. The compressed air savings is easy to calculate and proves to be dramatic. Payout for Air Nozzles and Jets, including filter and installation cost is measured in weeks - not years, as is the case for other cost reduction equipment. Based on a 40 hour work week, 52 weeks a year.

Example:

1. Existing blowoff is 1/8" open pipe at 80 PSIG (5.5 BAR) supply.

Air consumption, from the table above, is 70 SCFM (1,981 SLPM).

2. Use a 1/8 FNPT Model 1102 Mini Super Air Nozzle also at 80 PSIG (5.5 BAR) supply. Air consumption, from the image below, is 10 SCFM (283 SLPM).

3. Compressed air saved = 70 - 10 = 60 SCFM (1,981 - 283 =1,698 SLPM)

4. For this example, the blow off is continuous. If the duty cycle was 20%, then air saved would be 60 x .2 = 12 SCFM (1,698 x .2 = 340 SLPM).

5. Most large plants know their cost per 1,000 standard cubic feet of compressed air (10,000 standard liters). If you don't know your actual cost per 1,000 SCF, Rs 29 is a reasonable average to use.

(Cost per 10,000 standard liters is approximately Rs 10 )

6. Money saved per hour = SCFM saved x 60 minutes x cost/1,000 SCF

(SLPM saved x 60 min x cost/10,000 SL)

= 60 x 60 x Rs 29 /1,000

(= 1,698 x 60 x Rs 10 /10,000)

=Rs 104/hour that is =Rs 4160/week and Rs 216,320/year savings for one nozzle.

Now please Let me answer and explain to a very common question, we are asked during presentation of Exair's Air Nozzles that Why Exair Air nozzles consume less compressed air.

Well, we will discuss the working principle of Exair Air Nozzles and which is of course the realistic answer.

Air Nozzles use the Coanda effect to amplify compressed airflow up to 25 times or more. As illustrated on top, compressed air (black arrows) is ejected through a series of nozzles on the outer perimeter. As the air travels along the outer wall of the nozzle, surrounding air (blue arrows) is entrained into the stream. The airstream that results is a high volume, high velocity blast of air at minimal consumption. The air is always ejected so it can vent safely, well below OSHA dead end pressure requirements, should the nozzle end be blocked.

For more detailed information or to select the appropriate model for your specific needs, you can visit official website of Vivek Engineers or contact the Application Engineers.

website www.vivekengineers.net

Padmalochan Nayak

Vivek Engineers #22, 1st Floor, 1st Cross, Bilekahalli Indl. Area, Adj. IIMB Compound, Bannerghatta Road, Bangalore - 560 076 |

Monday, 29 July 2024

Exair Reversible Drum Vac: Efficient Liquid Handling for Industrial Applications

If You want to recover Coolant, Hydraulic Oils, Liquid spills, Sludge and Chips, Tramp Oil and Waste Water spills in industrial environments, then we suggest to go for Exair Reversible Drum Vac.

Dear reader, allow me to introduce you to the EXAIR Reversible Drum Vac.

The Exair Reversible Drum Vac is an industrial vacuum system designed to efficiently and quickly convert a standard 55-gallon drum into a powerful liquid vacuum. This tool is particularly useful for applications involving the cleanup of spills, transfer of liquids, and recovery of coolant, oil, or other fluids. Here's an overview of the Exair Reversible Drum Vac, including its features, benefits, and applications:

Overview

The Exair Reversible Drum Vac uses compressed air to create a vacuum within a drum, enabling it to draw in liquids quickly. The unique feature of this system is its reversibility, allowing users to empty the drum just as easily as it is filled.

Key Features

Reversible Operation:

- Fill and Empty: With the turn of a knob, the Reversible Drum Vac can switch from filling the drum to emptying it, providing a versatile solution for fluid handling.

Safety and Compliance:

- No Electricity: Operates on compressed air, eliminating the risk of electrical hazards.

- Automatic Safety Shutoff: Includes a safety shutoff valve to prevent overfilling.

Durability and Construction:

- Rugged Design: Built to withstand harsh industrial environments with a stainless steel pump for longevity.

- Maintenance-Free: The system has no moving parts, reducing maintenance needs and increasing reliability.

Ease of Use:

- Quick Setup: Easy to install and operate with minimal setup time.

Benefits

Efficiency:

- Fast Operation: Capable of filling or emptying a 55-gallon drum in less than two minutes.

- High Capacity: Ideal for handling large volumes of liquid quickly.

Cost-Effective:

- Energy-Efficient: Uses compressed air efficiently, minimizing air consumption ( 19 SCFM air consumption ).

Versatility:

- Multiple Applications: Suitable for a wide range of liquids, including coolant, oil, water, and sludge.

- Portable: Can be easily moved between different drums and locations within a facility.

Applications

Spill Cleanup:

- Quick Response: Efficiently handle accidental spills in industrial environments.

- Recovery: Recover valuable liquids and minimize waste.

Liquid Transfer:

- Coolant Recovery: Transfer coolant from machines to storage or filtration systems.

- Oil Change: Remove used oil from machinery and equipment for disposal or recycling.

General Maintenance:

- Sump Cleaning: Clean out sumps, tanks, and pits without manual scooping.

- Machinery Maintenance: Remove liquid waste from machinery during maintenance operations.

Accessories

- Drum Dolly: Provides mobility for the drum, making it easier to move the system around a facility.

- Drum Lid: A sealed lid with connections for the vacuum system to ensure a secure and efficient operation.

- Extension Wands and Hoses: Extend the reach of the system for cleaning hard-to-reach areas.

Conclusion

The Exair Reversible Drum Vac is a robust and versatile solution for industrial liquid handling needs. Its ability to quickly switch between filling and emptying modes, combined with its maintenance-free operation and safety features, make it an essential tool for many industries. For more detailed information or to select the appropriate model for your specific needs, you can visit official website of Vivek Engineers or contact the Application Engineers.

website www.vivekengineers.net

Vivek Engineers #22, 1st Floor, 1st Cross, Bilekahalli Indl. Area, Adj. IIMB Compound, Bannerghatta Road, Bangalore - 560 076 |

Wednesday, 3 July 2024

Exair Cabinet Cooler Systems

Exair(USA) offers a variety of Cabinet Cooler Systems designed to keep electrical enclosures cool by using compressed air to provide a low-cost and reliable solution. Here are some types of Cabinet Coolers that Exair offers:

NEMA 12 Cabinet Coolers: Designed for industrial environments where no liquids or corrosives are present, these coolers provide a reliable and low-cost way to cool electrical enclosures. They are dust-tight and oil-tight.

NEMA 4 Cabinet Coolers: These are used in wet, damp, and/or corrosive environments. They offer the same cooling power as the NEMA 12 models but are more robust against moisture and contaminants. They are dust-tight, oil-tight, splash resistant, indoor/outdoor service incorporate a low pressure relief valve for both the vortex tube and cabinet air exhaust. This valve closes and seals when the cooler is not operating to maintain the integrity of a NEMA 4 enclosure.

NEMA 4X Cabinet Coolers: Offer the same protection as NEMA 4, but ideal for corrosive or washdown environments, such as food processing and corrosive environments. They are made from stainless steel to resist corrosion.

High Temperature Cabinet Coolers: For ambient temperatures of 125° to 200°F (52° to 93°C) are available. Internal components can withstand high temperatures (like those near furnaces, ovens, etc.).They are suitable for locations with high ambient heat.

Non-Hazardous Purge Cabinet Coolers: are ideal for dirty areas where contaminants might normally pass through small holes or conduits. Under normal conditions, the NHP Cabinet Cooler Systems provide a slight positive pressure in the enclosure by passing 1 SCFM (28 SLPM) of air through the cooler, when the solenoid valve is in the closed position. When the thermostat detects high temperature, it energizes the solenoid valve to pass full line pressure and volume of compressed air to the Cabinet Cooler, giving it full cooling capability

Hazardous Location Cabinet Coolers: Hazardous Location NEMA 4 (IP66) Cabinet Coolers are engineered and approved for use upon purged electrical enclosures found within classified areas. The areas approved are Class I Div 1, Groups A, B, C and D; Class II Div 1 Groups E, F and G; and Class III. These HazLoc Cabinet Cooler Systems have been tested by UL and meet the stringent UL requirements for these areas. Cabinet Cooler systems are a low cost and reliable way to cool purged electric control panels found within these environments.

Cabinet Coolers - ATEX: ATEX Cabinet Cooler Systems are engineered and approved for use upon purged electrical enclosures (not included) found within ATEX zoned areas. The areas approved are Zone 2 and 22.

These coolers are available in different cooling capacities to suit various application needs, ranging from small control panels to large enclosures with significant heat loads. Please fill the Sizing Guide and send to us to recommend the perfect model for your panel/enclosure.

For more information contact us at below contact details or visit our website www.vivekengineers.net

Vivek Engineers #22, 1st Floor, 1st Cross, Bilekahalli Indl. Area, Adj. IIMB Compound, Bannerghatta Road, Bangalore - 560 076 Mob: 9740439220 |