In various industries, it is a very common issue, that is increase of temperature of a particular spot or small tools/ parts of machines during production process. Literally we can say a small issue can affect whole production process.

Also it is really uneconomical to facilitate air conditioning entire factories and workshops. If do so, then the main problem will arise as their sizes and other problems will be the various heats generated by production processes. Also it will be really uncontrollable to stop the cold air escaping through windows, open doors and loading bays. Of course the industry will need a high capacity air conditioning system i.e. expensive to purchase and also not cost effective to operate.

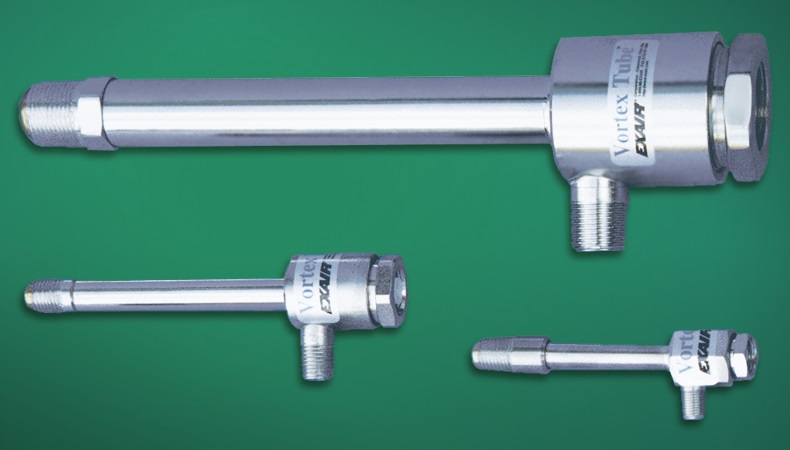

To resolve this problem EXAIR-USA has produced some Industrial spot cooling products . In this article I will discuss about EXAIR Vortex tube and the Cold Fraction generated by it which can produce cold air to a temperature as low as -46°C (-50°F) and most interesting matter is that it has no moving parts, so no tear and wear and made up of stainless steel which is wear resistance, as well as its resistance to corrosion and oxidation. So Exair provides a Industrial spot cooler i.e. Vortex Tube which will provide years of reliable, maintenance-free operation.

EXAIR Vortex Tubes are available in three sizes such as small, medium, and large. These sizes can produce a range of cooling capacities from 135 BTU/hr to 10,200 BTU/hr (34 Kcal/hr to 2,570 Kcal/hr).A generator plays vital role inside each Vortex Tube to provide such cooling effect. When the compressed air enters into the vortex tube, then it is controlled by the generator that can enter the Vortex Tube and initiating the spinning of the air.

As an example, a medium-sized Vortex Tube, model 3240, will only allow 40 SCFM (1,133 SLPM) of compressed air to travel into the Vortex Tube at 100 PSIG (6.9 bar). While a small-sized Vortex Tube, model 3208, will only allow 8 SCFM (227 SLPM) of compressed air at 100 PSIG (6.9 bar). EXAIR manufactures the most comprehensive range, from 2 SCFM (57 SLPM) to 150 SCFM (4,248 SLPM).

After the compressed air goes through the generator, there will be a pressure drop to slightly above atmospheric pressure. (This is the “engine” of how the Vortex Tube works). The air will travel toward one end of the tube, where there is an air control valve, or Hot Air Exhaust Valve. This side of the Vortex Tube will blow hot air. This valve can be adjusted to increase or decrease the amount of air that leaves the hot end. The remaining portion of the air is redirected toward the opposite end of the Vortex Tube, called the cold end. By conservation of mass, the hot air and cold air flows will have to equal the inlet flow as shown in Equation 1:

Equation 1:

Q = Qc + Qh

Q – Vortex Inlet Flow (SCFM/SLPM)

Qc – Cold Air Flow (SCFM/SLPM)

Qh – Hot Air Flow (SCFM/SLPM)

The percentage of inlet air flow that exits the cold end of a vortex tube is known as the Cold Fraction. As an example, if the Hot Air Exhaust Valve of the Vortex Tube is adjusted to allow only 20% of the air flow to escape from the hot end, then 80% of the air flow is redirected toward the cold end. EXAIR uses this ratio as the Cold Fraction; reference Equation 2:

Equation 2:

CF = Qc/Q * 100

CF = Cold Fraction (%)

Qc – Cold Air Flow (SCFM/SLPM)

Q – Vortex Inlet Flow (SCFM/SLPM)

EXAIR created a chart to show the temperature drop and rise, relative to the incoming compressed air temperature. Across the top of the chart, we have the Cold Fraction and along the side, we have the inlet air pressure. As you can see, the temperature changes as the Cold Fraction and inlet air pressure change. As the percentage of the Cold Fraction becomes smaller, the cold air flow becomes colder, but the amount of cold air flow becomes less. You may notice that this chart is independent of the Vortex Tube size. So, no matter the generator size of the Vortex Tube that is used, the temperature drop and rise will follow the chart above.

How do you use this chart? As an example, we can select a model 3230 Vortex Tube. It will use 30 SCFM (850 SLPM) of compressed air at 100 PSIG (6.9 Bar). We can determine the temperature and amount of air that will flow from the cold end and the hot end. For our scenario, we will set the inlet pressure to 100 PSIG, and adjust the Hot Exhaust Valve to allow for a 60% Cold Fraction. Let’s say the inlet compressed air temperature is 68°F. With Equation 2, we can rearrange the values to find the Cold Air Flow, Qc:

Qc = CF * Q

Qc = 0.60 * 30 SCFM = 18 SCFM of cold air flow

The temperature drop shown in the chart above is 86°F. If the inlet temperature is 68°F, the temperature of the cold air is (68°F – 86°F) = -18°F. So, at the cold end, we will have 18 SCFM of air at a temperature of -18°F. For the hot end, we can calculate the flow and temperature as well. From Equation 1,

Q = Qc + Qh or

Qh = Q – Qc

Qh = 30 SCFM – 18 SCFM = 12 SCFM

The temperature rise shown in the chart above is 119°F. So, with the inlet temperature at 68°F, we get (119°F + 68°F) = 187°F. So, we have 12 SCFM of air at a temperature of 187°F coming out of the hot end.

With the Cold Fraction and inlet air pressure, you can get specific temperatures for your application. For cooling and heating capacities, the flow and temperature can be used to calculate the correct Vortex Tube size for your application.

Padmalochan Nayak

Vivek Engineers #22, 1st Floor, 1st Cross, Bilekahalli Indl. Area, Adj. IIMB Compound, Bannerghatta Road, Bangalore - 560 076 Ph : 080 - 2648 1309, 4170 1145. | |||

No comments:

Post a Comment