Atomizing Spray Nozzles

A Model AN1010SS Internal Mix Narrow Angle Round Pattern Atomizing Nozzle is used to mark strips of steel before they leave the mill.

|

A Model SR1010SS Siphon Fed RoundPattern Atomizing Nozzle is used to supply a cooling mist for a drilling operation. |

Model EB1030SS External Mix Wide Angle Flat Fan Pattern Atomizing Nozzles are used to give a final sanitary rinse prior to labeling wine bottles. |

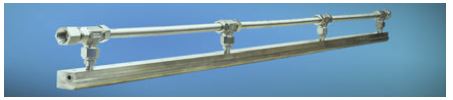

EXAIR’s atomizing spray nozzles atomize fluids(most commonly water) in a range of spray patterns for a variety of uses. They combine liquid and compressed air to create a mist of atomized liquid that can be easily adjusted to meet the needs of your application. All models use stainless steel construction for durability and corrosion resistance.

EXAIR's atomizing nozzles are available in 3 basic families:

Internal Mix:

Internal mix nozzles mix the liquid and water inside the air cap and produce the finest atomization. Internal mix nozzles can be used on liquids with aviscosity up to 300 cp. Both air and liquid sides are pressure fed. >More

External Mix:

External mix nozzles have the highest flow rates and allow the air and liquid flows to be adjusted independently. These nozzles are best where precise liquid flow is needed. External mix nozzles can be used on liquids with a viscosity above 300 cp. Both air and liquid sides are pressure fed.>More

Siphon Fed:

Siphon fed nozzles require no liquid pressure and can be used with gravity fed liquids or lift liquids from a siphon height as much as 36 inches (91cm). Siphon fed nozzles can be used on liquids with a viscosity up to 200 cp. >More